10 Best Metal Cut-off Wheels [2025]

This post contains affiliate links. As an Amazon Associate, we earn from qualifying purchases.

Finding the best metal cut-off wheels for your specific needs can be a daunting task, given the plethora of options available on the market. To simplify your search, we meticulously shortlisted 10 top products based on performance, durability, and user reviews, ensuring they meet a variety of cutting requirements. Our curated list not only saves you time but also alleviates the hassle of sifting through countless choices, allowing you to select the perfect metal cut-off wheel with confidence.

Top 10 Metal Cut-off Wheels In The Market

Metal Cut-off Wheels Review

- More Cuts. Fewer Wheels.TM

- 50% Longer Life* Replace wheels less often with Temper Point grains that are tougher and razor sharp for more cuts. Better adhesion between the coated grains and resin creates a longer lasting cutting edge that wears slowly.

- Extremely Versatile: Efficiently cut a wide range of metals including carbon steel, stainless and nickel-based alloys.

- Aggressive Cutting Action: Make fast cuts with a thin wheel design and high-grain concentration.

- Durable By Design: Built with two sheets of fiberglass for wheel strength. Designed to reduce wheel breakage.

- Premium Aluminum Oxide Blend - a superior quality formulation designed for fast material removal and long cutting life.

- Type 1 - Flat.

- For use on metal applications: steel, stainless, cast iron, sheet metal.

- Includes (10) DBD045040101F Cut-Off Discs.

- 4-1/2 in. Metal Cut Off Disc - Thin Kerf.

- [Diamond Technology] 1 equals 100, EZARC diamond cut off wheel delivers 5,000+ more cuts for metal with much lower cost per cut compared to bonded cut-off wheels

- [All in 1 Metal Solution] Ideal for dry cutting of metal, rebar, iron, alloy steel, aluminum, different types of pipes and sheet metal with over 100X longer life than bonded cutoff wheels in metal cutting applications

- [Avoid Injury] Solid steel wheel body greatly reduces risk of shatter and injury for added safety, increased productivity. The metal cutting disc is 100% contaminant-free, it does not wear down like bonded abrasives reducing dust particles for a cleaner work station

- [Industrial Quality] Quality Assured accurate cutting PERFORMANCE, PRECISION, LONGEVITY, STABILITY & INTEGRITY, cutting Longer, Faster and Reliably than other wheels that may shatter or prematurely wear

- [Accurate Cutting] This cut-off wheel for metal maintains original wheel diameter throughout the life of the blade for better control and precision cutting

- Size :4-1/2-inch x .047-inch x 7/8-inch

- Performance: this is for a pack of 50 pieces of our cutting wheels thin 0.045" Cutting wheel design for fast burr free cutting. Perfectly compatible with all 4-1/2 angle grinders with 7/8-inch arbor, operating up to 13,300 rpm and 80m/s

- Advantage: thin .045-inch wheel design for fast burr free cutting proprietary aluminum oxide grain combination for aggressive cutting action

- Material: proprietary aluminum oxide grain for long life and fast cutting.double fiberglass mesh reinforced for further safety and durability

- Safety tips: please use all necessary protective gear when you use these cutting discs.if there is any problem with the product, please contact us to help you solve the after-sales problem

- 【IDEAL SIZE】With a diameter of 4.5" (115mm), segments thickness of .068" (1.73mm), arbor hole of 7/8" (22.23mm), and reducer washer of 16mm (5/8"), reducer washer of 20mm (4/5"), our blade is the perfect size for your cutting needs.

- 【PRECISE METAL CUTTING】Achieve accurate, chip-free cuts with our diamond metal cut off disc. Its upgraded blade features a diamond high manganese steel substrate and new brazing process for longer service life, high temperature resistance, and low noise.

- 【SHARP BLADE】WildBossy diamond cutting blade cuts fast and straight with uniform grinding force, good flatness, and less chips. It's also more durable than other blades.

- 【EASY TO INSTALL AND USE】The diamond cutting wheel is the perfect angle grinder cutting disc for cutting normal steel in structures, metal pipes, and galvanized steel.

- 【VERSATILE】With a metal cutting blade designed for toughness and precision, this cutoff wheel is ideal for use on rebar, steel, iron and INOX.

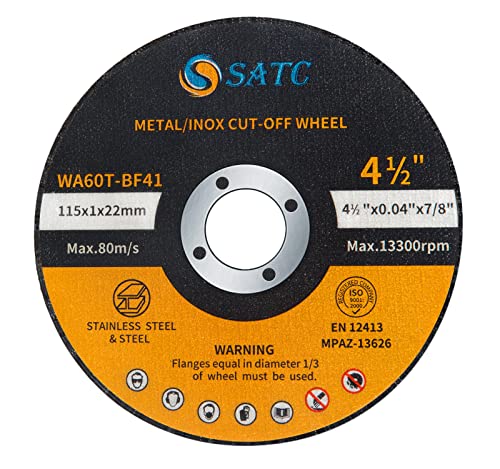

- LONGEST LASTING:Cut off wheels feature metal center and ultra-thin 0.040" thickness. 50 pieces cutting disc for metal & stainless steel meet ANSI safety requirements. Grinder Wheel Dimensions: 4 1/2"x0.040"x7/8"

- PERFECT ALUMINUM:4 1/2 cut off wheel is made with a proprietary combination of alumina particles for aggressive cutting action, providing the industry's best balance of cut life, cut rate, cut accuracy, power requirements and heat build-up, to give you unmatched cut time, consistent precise integrity, moderate power requirements and relatively low heat build-up

- FITS ANY ANGLE GRINDER:50 PCS cut-off wheels for metal & stainless steel fast burr-free cutting feature 4 1/2"x0.040"x7/8" , compatible with Die Grinder, Air Cut Off Tool and Electric Cut Off Tool

- MULTIPLE UESES:Cut off wheels 4 1/2 inch are designed for cutting fiberglass, steel, iron, plastic, stainless steel including rebar, steel pipe, structural & galvanized steel, sheet metal, structural tubing, black steel , and other ferrous metals

- Attention Please:Cutting disc is made in accordance. Before using these, please wear all applicable safety gear when using these discs (eyes/ears/face/hands/body/etc)

- 【LONG LIFE & SMOOTH CUTTING】Merryland Cut off Wheel 4.5 inch Metal Stainless Steel Cutting for Angle Grinder. Made of German Phenolic Resin, Refined Calcined & White Corundum. Craft-Line. High Quality and Long Life!

- 【REINFORCED STRUCTURE & SAFETY GUARANTEED】4-1/2 X 0.045 X 7/8 Ultra Thin Cutting Wheel. 0.045 Thickness Professional Cutting Disc, 2 Layers of Reinforced Fiberglass Mesh, Max RPM 13300, According to European Standard EN 12413, MPA Certified. Safety Guaranteed!

- 【WIDE APPLICATION & UNIVERSAL USE】Metal, Iron, Stainless / INOX, Steel, Sheet Metal, Plastic, Steel Pipe. Suitable for Cutting a Wide Range of Materials. C31071042 is GOOD at UNIVERSIAL Cutting!

- 【EASY OPERATION & STABLE PERFORMANCE】Angle Grinder and Cutting Machine with 4.5” Diameter and 7/8” Bore are Suitable for This Disc. Fast and Accurate Cut-off Wheel!

- 【MASTER DESIGN & HANDY TOOL】50 Pack / Box, A Safety Manual in the Box. An Ideal Cutting Tool for Who Love Metal Working!

- Specifications: PRETEC diamond cut off wheel diameter 4-1/2 in (115 mm), hole diameter 7/8 in (22.23 mm), thickness 0.074 inch (1.9 mm); The maximum safe operating speed is 13,300 RPM. Our 4 1/2 metal cutting blade size is very suitable for your cutting needs.

- Diamond Technology: Compared with bonded cutting wheel, PRETEC diamond cut off wheel uses industrial grade diamond at the edges to form an indestructible blade that can cut metals more than 6000 times. Extending the service life of the 4 1/2 cut off wheel by 100 times longer and making it more durable, higher productivity, less downtime, and lower cutting costs per cut.

- Safe and Efficient: The solid steel body of cut off wheels 4 1/2 inch greatly reduces the risk of injury caused by damage, and the diamond blade reduces sparks during cutting, resulting in fast cutting speed, good flatness, less dust, and a cleaner working environment.

- Heat Dissipation and Dust Removal Design: The 4.5 cut off wheel for metal edge adopts a circular hole design, which can enhance the heat dissipation function. Groove design can accelerate debris removal, improve cutting efficiency and flatness.

- Comprehensive Metal Solution: Our angle grinder cutting disc are designed for toughness, precision, and longer service life. Very suitable for cutting metal, steel bars, iron, alloy steel, aluminum, different types of pipes and metal plates.

- Perfect Size: Perfectly compatible with all 4-1/2 inch(115mm) angle grinders with 7/8 inch(22.2mm) arbor. Thickness:0.045 inch(1.2mm). Operating up to 13,300 RPM

- Precise & Quickly: 0.045 inch ultra thin design for fast burr free and precise cutting perforamce with minimal material loss

- Safety - Avoid Wheel Shatter: Metal cutting discs are made of aluminum oxide grains. More safe than other wheels that may shatter or prematurely wear. Wear all applicable safety gear when using these discs (eyes/ears/face/hands/body/etc)

- Durable: Bonded with corundum and white alundum grain and reinforced by double fiberglass mesh, these cutting discs perform much more aggressive cutting longer, faster and reliably than other wheels that may shatter or prematurely wear

- Multiple Use: Cutting discs are designed for hard and continuous use on all metal, fiberglass, iron, plastic, steel and stainless steel parts including rebar, steel pipe, structural & galvanized steel, sheet metal, structural tubing and other ferrous metals for aggressive cutting action

- Premium and Value: This 10-pack 4-1/2 x 7/8-inch metal/stainless steel cut-off wheel set is specially formulated for fast cutting in metals and stainless steel

- Safe but Durable Material: Bonded with corundum and white alundum grain and reinforced by double fiberglass mesh, these cutting discs perform much more aggressive cutting in metal and stainless with safety and longer service life

- Precise and Efficient Cutting: 3/64-inch ultra thin design for fast burr-free cutting with minimal material loss, making the cutting project more precise and efficient

- Great Performance: Perfectly compatible with all 4-1/2 inch angle grinders with 7/8-inch arbor, operating up to 13,000 RPM and 80M/S

- Versatile Applications: Tough abrasive cutting discs are perfect for super-fast, clean cutting in carbon steel, stainless steel, pipe, iron, copper and all other ferrous metals

Our Review Process

To ensure you get reliable product recommendations, we follow a detailed review methodology that includes:

- Market Research: Scanning best-selling and trending products in this category.

- User Feedback: Reviewing customer reviews, star ratings, and complaints.

- Hands-On Testing: Trying select products ourselves when feasible.

- Feature Comparison: Evaluating specs, durability, pricing, and safety.

- Expert Opinions: Consulting with niche experts or credible reviewers.

We independently select the top 10 options based on value, quality, and usability. To learn more, visit our detailed review process.

Key Considerations Before Buying Metal Cut-off Wheels

1. Type of Metal

Understanding the type of metal you will be cutting is crucial when selecting cut-off wheels. Different metals, such as steel, aluminum, or stainless steel, require specific wheel compositions to achieve optimal cutting performance. For instance, aluminum may require a wheel designed to reduce clogging, while stainless steel may need a wheel that minimizes heat generation.

2. Wheel Material

Cut-off wheels are typically made from materials like aluminum oxide, zirconia, or silicon carbide. Each material has its own advantages and is suited for different types of applications. Aluminum oxide wheels are ideal for general-purpose cutting, while zirconia wheels provide better durability for tougher materials. Consider the material of the wheel to ensure it complements your cutting tasks.

3. Wheel Thickness

The thickness of the cut-off wheel affects both the cutting speed and the finish of the cut. Thinner wheels (usually around 1/16 inch) allow for quicker cuts and less material loss, making them ideal for precision work. Thicker wheels (typically 1/8 inch or more) are more durable and can handle heavier cuts but may produce a rougher finish. Choose the thickness based on your specific cutting needs.

4. Size and Compatibility

Cut-off wheels come in various diameters and sizes. It’s essential to choose a size that is compatible with your cutting tool, whether it’s a handheld grinder, a stationary saw, or a chop saw. Always check the specifications of your equipment to ensure the wheel fits properly and can be safely used.

5. RPM Rating

Each cut-off wheel has a maximum RPM (revolutions per minute) rating. It’s important to select a wheel whose RPM rating matches or exceeds the RPM of your tool to avoid safety hazards and ensure effective performance. Using a wheel with a lower RPM rating than required can lead to breakage and accidents.

6. Application and Usage

Consider the specific applications for which you will be using the cut-off wheel. If you need to perform heavy-duty cutting tasks or work on various materials, opt for a high-performance wheel designed for versatility. Alternatively, if your tasks are more specialized, such as cutting thin sheet metal, a wheel tailored for that application may be more suitable.

7. Brand and Quality

The brand and overall quality of the cut-off wheel can significantly impact performance and safety. Choose reputable manufacturers known for producing high-quality products. Investing in quality cut-off wheels may result in better cutting efficiency, longer life span, and improved safety during operation.

8. Safety Features

Safety should always be a priority when selecting cut-off wheels. Look for wheels that have been tested for durability and safety compliance. Some wheels come with additional safety features, such as reinforcements or specific designs to reduce the risk of breakage. Always read the guidelines provided by the manufacturer to ensure safe usage.

FAQs

What are metal cut-off wheels used for?

Metal cut-off wheels are designed for cutting through various types of metal materials. They are commonly used in applications such as metal fabrication, construction, and maintenance, providing a clean and precise cut for tasks like cutting pipes, sheets, and rods.

What materials can be cut with metal cut-off wheels?

Metal cut-off wheels can be used to cut a range of materials including steel, stainless steel, aluminum, and other ferrous and non-ferrous metals. It’s important to select the right wheel for the specific material to ensure optimal performance and safety.

How do I choose the right cut-off wheel for my project?

To choose the right cut-off wheel, consider the following factors: the type of material you will be cutting, the thickness of the material, the size of the cut-off wheel, and the compatibility with your cutting tool. Always refer to the manufacturer’s specifications for guidance.

What is the difference between thin and thick cut-off wheels?

Thin cut-off wheels are generally 1/16 inch thick and are designed for making precise, shallow cuts with minimal material loss. Thick cut-off wheels, which are often 1/8 inch or thicker, are more durable and better suited for cutting thicker materials but may produce more heat and require more force.

Can I use metal cut-off wheels on different types of grinders?

Yes, metal cut-off wheels can be used on various grinders, including angle grinders and bench grinders. However, ensure that the wheel’s size and specifications match the grinder’s capabilities and always follow the manufacturer’s guidelines for safe operation.

What safety precautions should I take when using metal cut-off wheels?

When using metal cut-off wheels, always wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and a face shield. Ensure that the workspace is clear of flammable materials, and always secure the workpiece to prevent movement during cutting.

How long do metal cut-off wheels last?

The lifespan of metal cut-off wheels depends on several factors including the material being cut, the thickness of the wheel, and the operator’s technique. Generally, a wheel can last anywhere from a few cuts to several hundred cuts, so monitoring wear and replacing them as needed is essential.

Can I use a cut-off wheel for grinding?

No, cut-off wheels are specifically designed for cutting, not grinding. Using a cut-off wheel for grinding can compromise its integrity and lead to breakage or accidents. For grinding tasks, always use a designated grinding wheel.

What is the best way to store metal cut-off wheels?

Store metal cut-off wheels in a cool, dry place away from direct sunlight and extreme temperatures. Keep them in their original packaging or in a protective case to prevent damage and ensure longevity.

Are there any specific maintenance tips for metal cut-off wheels?

While metal cut-off wheels do not require extensive maintenance, it’s important to regularly inspect them for wear, cracks, or damage. Always clean the cutting area and ensure the wheel is properly mounted and secured before use.

The Bottom Line

In conclusion, selecting the right metal cut-off wheels is crucial for achieving optimal performance and safety in your cutting tasks. Our curated list of the ten best metal cut-off wheels reflects extensive research, user reviews, and expert recommendations to ensure that you have access to top-quality products. Each wheel was evaluated based on factors such as material compatibility, durability, cutting speed, and overall value for money. By focusing on these key attributes, we aimed to provide a comprehensive guide that caters to both DIY enthusiasts and professionals alike.

Following our list not only simplifies your purchasing decision but also enhances your cutting experience. By choosing from these top-rated products, you can improve efficiency and accuracy in your projects while minimizing the risk of errors or accidents. Whether you’re working on metal fabrication, automotive repairs, or construction tasks, the right cut-off wheel can make all the difference. Trust our recommendations to equip you with the best tools for your cutting needs, making your work more productive and enjoyable.