10 Best Grinding Wheels For Tungsten Electrodes [2025]

This post contains affiliate links. As an Amazon Associate, we earn from qualifying purchases.

Finding the best grinding wheels for tungsten electrodes can be a daunting task, especially with the vast array of options available on the market. To simplify your search, we meticulously shortlisted 10 top-quality products, considering factors such as durability, efficiency, and user feedback. Our curated list aims to save you time and hassle, ensuring you choose the perfect grinding wheel that meets your specific needs without the overwhelming process of sifting through countless choices.

Top 10 Grinding Wheels For Tungsten Electrodes In The Market

Grinding Wheels For Tungsten Electrodes Review

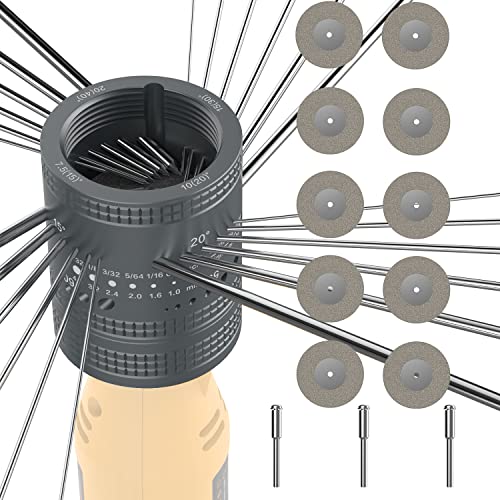

- This Diamond wheel is compatible with our 3mirrors tungsten electrode sharpener grinders, Dremel, Wen and other Rotary Tools. Please check what you need is 25MM OR 35MM wheels before purchase.

- Package includes: 10 x 25 mm cutting discs/ Full Sand Diamond wheels; 2 x 35 mm Mandrels/ Connecting Rods(NEW CNC UPGRADE, More Durable).

- Material: High Quality Carbon Steel, more durable than ordinary grinding wheel. Disc Diameter: 25 mm.

- DIY cost-effective parts. Full sand Diamond Wheels, Wheel and the sharping system are great to use. With good hardness, wear resistance and good impact resistance.

- These Cutting Wheels fit most rotary and air tools. Also, can be used with your rotary tool to cut a wide variety of materials like wood, metal, gem, jade, glass, plastic, aluminum alloy, soft metal etc.

- Double-Sided Available Diamond Wheel: Both sides of the diamond wheel can be used, so it has a long-use life

- Application: It can only be used with YESWELDER's Sharpener Grinder

- Package Include: 1Pcs Diamond Wheel and 2Pcs Carbon Brush

- Wide Adaptability: Welding equipment for all rotary tools with a 3/4-12 thread, including fit for Black and Decker, fit for Milwaukee, fit for Bosch Dremel, packaging includes 1 tungsten electrode angle controller, 1 connecting rod, 5 diamond wheels, 1 installer, four angled holes for use: 22.5 °, 20 °, 15 °, and 10 °, 4 guide rails is 0/40", 1/16", 3/32" and 1/8"

- High Quality Materials: Different materials of electrodes may require different grinding materials and methods. Electrode grinders can effectively remove surface impurities through grinding operations, restore the electrode surface, and improve the conductivity of the electrode

- Improve Electrode Performance: Impurities on surface of electrode are removed by grinding tungsten grinder, conductivity and thermal conductivity of the electrode are improved. Good conductivity and thermal conductivity can effectively reduce electrode heating in high current and high-power applications

- Corrosion Resistant and Wear-Resistant: After grinding, the electrode surface of the tungsten electrode angle controller becomes denser, forming a uniform protective film that can enhance the corrosion resistance and wear resistance of the electrode

- Cost Savings: In harsh working environments, tungsten electrode sharp grinder can better resist corrosion, maintain stable performance, and withstand a certain degree of friction and wear, extending its service life and saving maintenance costs

- Double-sided, Premium Diamond Grinding Wheel.

- The Red center is used to identify our "Best" replacement diamond wheel for Arc-Zone's Sharpie hand-held tungsten electrode grinders.

- Arc-Zone's Premium smooth grit diamond grinding wheels are of the highest quality, made with Premium Industrial Grade Diamond Media for long, trouble-free grinding.

- Arc-Zone's Premium smooth grit diamond grinding wheels are of the highest quality, made with Premium Industrial Grade Diamond Media for long, trouble-free grinding.

- Made in the USA.

- Diamond impregnated double sided wheel for sharpening Tungsten Electrodes

- Get 100 sharpening’s on each side for a total of 200 sharpenings per wheel

- These wheels fit the TG1800 (33307) and the original Eastwood TIG Welder Tungsten Grinder (21526)

- Use these as a back-up for TIG Welding jobs so you do not run out

- Eastwood Offers 100% Satisfaction and Lifetime Technical Support

- NOTE: ONLY Tungsten Electrode Sharpener Grinder Head, NO Electric Grinder

- Easy Operation: All the holes are fixed, when you need Tungsten Electrode with different angles, you only need to insert the tungsten electrode into the corresponding holes, no need to re-adjust the height of the diamond grinding wheel. We also set an offset compensation for each hole size to ensure that the tip centers of all tungsten electrodes are on the grinding center point. Even a freshman can easily use SONNLER tungsten sharpener to grind out the desired angle.

- 6 Size 8 Angles: This grinding head supports 6 sizes of tungsten electrode ( 5/32", 1/8", 3/32", 5/64", 1/6", 040"), 8 angled holes: 7.5 °,10°, 15°, 20°, 22.5°, 25°, 27.5°, 30°.(15°, 20°, 30°, 40°, 45°,50°, 55°, 60° Tips Angle respectively). All grinding heads have been checked by precision measuring tools, ensuring the SONNLER tungsten sharpener can grind a perfect tungsten tip angle.

- Package Include: 10*Double Sided Grind Wheels, 3* CNC Mandrels,1* Tungsten Electrode Grinding Head

- Wearing a mask and other protective gear is recommended unless you are grinding in a full-sealed space. SONNLER Make For Higher Efficiency Welding If you have any questions, please contact us, we will provide professional help!

- Portable & High Performance: Are you still suffering from cumbersome grinding machines? This tungsten sharpening grinder is a hand-held tool, very convenient. This set includes a Tungsten Electrode angle Sharpener and an electric rotary tool, which is light and portable, more convenient, you can grind more tungsten needles with more perfect angles faster. Help you improve welding efficiency.

- 6 Size 8 Angles: This grinding head supports 6 sizes of tungsten electrode ( 5/32", 1/8", 3/32", 5/64", 1/6", 040"), 8 angled holes: 7.5 °,10°, 15°, 20°, 22.5°, 25°, 27.5°, 30°.(15°, 20°, 30°, 40°, 45°,50°, 55°, 60° Tips Angle respectively). All grinding heads have been checked by precision measuring tools, ensuring the SONNLER tungsten sharpener can grind a perfect tungsten tip angle.

- Easy Operation: All the holes are fixed, when you need Tungsten Electrode with different angles, you only need to insert the tungsten electrode into the corresponding holes, no need to re-adjust the height of the diamond grinding wheel. We also set an offset compensation for each hole size to ensure that the tip centers of all tungsten electrodes are on the grinding center point. Even a freshman can easily use the SONNLER tungsten sharpener to grind out the desired angle.

- Package Include: 10*Double Sided Grind Wheels, 3* CNC Mandrels, 1*Electric Grinder, 1* Tungsten Electrode Grinding Head, 1*Wrench, 1* Storage Box, 1* User Manual.1* Pin Vise Hand Drill

- SONNLER Make For Higher Efficiency Welding: Wearing a mask and other protective gear is recommended unless you are grinding in a full-sealed space. If you have any questions, please contact us, and we will provide professional help!

- 2 Diamond Abrasive Wheels

- Mounting Screw is not included

- 1" Diameter

- Double Sided Abrasive

- Max RPM 40 000

- Features an outer diameter of 125mm (5 inches) and an inner hole diameter of 22.23mm, compatible with standard grinders and sharpening tools.

- This 125mm tungsten carbide grinding disc is designed for efficient sharpening, grinding, and cutting of tungsten electrodes and other hard materials.

- Tested for a maximum load of 14,500 RPM, offering stability and safety during high-speed grinding applications.

- Made from hardened steel with an electroplated silicon carbide surface and oxide coating, ensuring durability and long-lasting performance.

- This diamond-coated grinding wheel is ideal for sharpening tungsten electrodes, tungsten carbide saw blades, dull drill bits, wood chisels, SDS bits, and lawn mower blades with precision and durability.

- Common Sizes and Angles: This grinding head have 4 common sizes of tungsten electrode 040", 1/6", 3/32", 1/8" ( 1.0mm, 1.6mm, 2.4mm, 3.2mm), 3 common angled: 15°, 22.5°, 30°. It's suitable for welding beginners, professionals and hobbyists

- Simple operation and Efficient: The fixed height and holes design made it only need to insert the tungsten electrode into the corresponding holes. Grinding has never been safer and more effortless

- Premium Quality: Our grinding head features a double-sided diamond wheel, with both sides being usable. Besides, the thickness is thicker than most ordinary wheels, ensuring a longer service life. Enjoy high-quality grinding without the need for frequent replacement

- Safety: The use of dust cover can concentrate on processing the tungsten power produced by grinding, avoid trouble, and is also conducive to health. And it is made of aluminum alloy material, CNC finishes are more durable, and there will not be high temperature melting

- Package Include: Electric Grinder*1, Storage Box*1, Hexagon Screwdriver*1, Acrylic Dust Cover*1, Carbon Brush*2

Our Review Process

To ensure you get reliable product recommendations, we follow a detailed review methodology that includes:

- Market Research: Scanning best-selling and trending products in this category.

- User Feedback: Reviewing customer reviews, star ratings, and complaints.

- Hands-On Testing: Trying select products ourselves when feasible.

- Feature Comparison: Evaluating specs, durability, pricing, and safety.

- Expert Opinions: Consulting with niche experts or credible reviewers.

We independently select the top 10 options based on value, quality, and usability. To learn more, visit our detailed review process.

Key Considerations Before Buying Grinding Wheels for Tungsten Electrodes

When selecting grinding wheels for tungsten electrodes, it’s essential to consider various factors to ensure optimal performance and safety. The right grinding wheel can significantly affect the quality of your welds and the longevity of your equipment.

1. Type of Grinding Wheel

Different types of grinding wheels are designed for specific applications. For tungsten electrodes, the most common types are:

- Diamond Grinding Wheels: These are highly recommended for grinding tungsten due to their durability and effectiveness in quickly removing material.

- Ceramic Grinding Wheels: These wheels can also be used but may not be as efficient as diamond wheels for tungsten.

2. Grit Size

The grit size of the grinding wheel affects the finish and precision of the tungsten electrode. Finer grits provide a smoother finish but may take longer to grind, while coarser grits remove material more quickly but can leave a rougher surface. A common recommendation is to start with a medium grit (around 120) and move to finer grits for precision work.

3. Bond Material

The bond material of a grinding wheel determines its strength and durability. Most tungsten grinding wheels use a resin or metal bond. Resin bonds offer good performance for general use, while metal bonds are more durable and suitable for high-volume grinding.

4. Wheel Diameter and Thickness

The diameter and thickness of the grinding wheel should match your grinding equipment and the size of the tungsten electrodes you intend to grind. A wheel that’s too thick may not provide the precision needed, while a wheel that’s too thin may wear out quickly.

5. Safety Features

Ensure the grinding wheel has appropriate safety ratings and features. Look for wheels that are rated for high RPMs and have a built-in safety mechanism to prevent breakage during operation. Always adhere to the manufacturer’s guidelines regarding maximum speed and usage.

6. Compatibility with Equipment

Before purchasing, confirm that the grinding wheel is compatible with your grinding machine. Check the arbor size and ensure it fits your equipment properly. Incompatibility can lead to inefficient grinding and potential safety hazards.

7. Price and Brand Reputation

While price is an important consideration, it’s essential to weigh it against the quality and brand reputation. Investing in a well-known brand may cost more upfront but can save money in the long run through improved performance and durability.

8. User Reviews and Recommendations

Always look for user reviews and recommendations before making a purchase. Feedback from other users can provide insights into the wheel’s performance, longevity, and value for money.

9. Environmental Factors

Consider the environment in which the grinding will take place. Dust control features and the presence of ventilation systems may also be important factors, especially when working with tungsten, which can create harmful dust particles.

10. Maintenance and Replacement

Finally, consider the maintenance requirements and how often you may need to replace the grinding wheel. Some wheels may require more frequent replacement due to wear and tear, while others may have a longer lifespan with proper maintenance.

FAQs

What is a grinding wheel for tungsten electrodes?

A grinding wheel for tungsten electrodes is a specialized abrasive tool designed to sharpen and prepare tungsten electrodes used in TIG (Tungsten Inert Gas) welding. These wheels are made from materials that can effectively grind the hard tungsten without causing excessive wear or contamination.

What types of grinding wheels are best for tungsten electrodes?

The best types of grinding wheels for tungsten electrodes are typically made from aluminum oxide or diamond abrasive. Diamond wheels are particularly effective for grinding tungsten due to their hardness and longevity, while aluminum oxide wheels are more commonly used and readily available.

How do I choose the right grit for my grinding wheel?

Choosing the right grit depends on the desired finish and the size of the tungsten electrode. For initial shaping, a coarser grit (around 60 to 80 grit) is suitable, while finer grits (120 to 400 grit) are better for achieving a smoother finish. Typically, a combination of grits may be used for optimal results.

Can I use a regular bench grinder for tungsten electrodes?

While a regular bench grinder can be used, it is recommended to use a dedicated grinder with a specific wheel designed for tungsten. This minimizes contamination and ensures a more precise angle for the electrode, which is crucial for effective welding.

What angle should I grind my tungsten electrodes?

The most common angles for grinding tungsten electrodes are 15 to 30 degrees. The specific angle may depend on the welding application; for example, a sharp point is often used for thin materials, while a flatter angle is preferred for thicker materials.

How often should I replace my grinding wheel?

The lifespan of a grinding wheel depends on usage and the type of wheel. Generally, you should replace the wheel when you notice a significant decrease in performance, such as difficulty in grinding or uneven wear. Regular maintenance can prolong the life of the wheel.

Can I use coolant while grinding tungsten electrodes?

Using coolant while grinding tungsten electrodes is not necessary and is often discouraged. Coolants can contaminate the tungsten, affecting its performance in welding. It’s usually recommended to grind dry and at a moderate speed to prevent overheating.

What are the safety precautions when using grinding wheels?

When using grinding wheels, always wear appropriate personal protective equipment (PPE), including safety goggles, gloves, and a dust mask. Ensure that the grinding wheel is properly installed, and avoid wearing loose clothing or jewelry that could get caught in the grinder. Always follow the manufacturer’s instructions.

Can I use the same grinding wheel for different types of electrodes?

While it is possible to use the same grinding wheel for different types of electrodes, it is generally better practice to use separate wheels for different materials to avoid contamination. This is especially important when grinding non-tungsten materials to prevent cross-contamination during welding.

Where can I buy grinding wheels for tungsten electrodes?

Grinding wheels for tungsten electrodes are available at welding supply stores, industrial tool suppliers, and online retailers. It is important to ensure that the wheel is specifically designed for tungsten to achieve the best results.

The Bottom Line

In conclusion, selecting the right grinding wheel for tungsten electrodes is crucial for achieving optimal performance and longevity in your welding projects. The ten products highlighted in this article were carefully chosen based on their material compatibility, durability, and user reviews. By considering factors such as grit size, wheel type, and the specific requirements of your welding application, we have compiled a list that caters to a variety of needs and preferences.

By following our list, you can significantly enhance your welding results and improve the efficiency of your electrode preparation. Whether you are a professional welder or a hobbyist, using the right grinding wheel will ensure that your tungsten electrodes maintain a sharp point and consistent arc stability. Investing in high-quality grinding wheels not only saves time and resources but also contributes to the overall quality of your welds. We hope this guide serves as a valuable resource in your pursuit of the best grinding wheels for tungsten electrodes.