10 Best Cut-off Wheels For Stainless Steel [2025]

This post contains affiliate links. As an Amazon Associate, we earn from qualifying purchases.

Finding the best cut-off wheels for stainless steel can be a daunting task, especially with the vast array of options available on the market today. To simplify your search, we meticulously shortlisted ten top-performing products based on quality, performance, and user reviews. Our curated list not only highlights the best choices but also saves you valuable time and effort, ensuring you find the perfect cut-off wheel to meet your needs without the hassle of sifting through countless options on your own.

Top 10 Cut-off Wheels For Stainless Steel In The Market

Cut-off Wheels For Stainless Steel Review

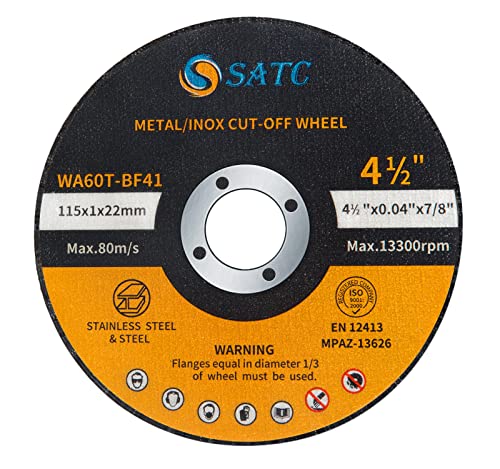

- Size :4-1/2-inch x .047-inch x 7/8-inch

- Performance: this is for a pack of 50 pieces of our cutting wheels thin 0.045" Cutting wheel design for fast burr free cutting. Perfectly compatible with all 4-1/2 angle grinders with 7/8-inch arbor, operating up to 13,300 rpm and 80m/s

- Advantage: thin .045-inch wheel design for fast burr free cutting proprietary aluminum oxide grain combination for aggressive cutting action

- Material: proprietary aluminum oxide grain for long life and fast cutting.double fiberglass mesh reinforced for further safety and durability

- Safety tips: please use all necessary protective gear when you use these cutting discs.if there is any problem with the product, please contact us to help you solve the after-sales problem

- 【50 PACK】This is for a pack of 50 pieces of our cutting wheels. Outer diameter:4.5inch inside diameter:7/8 inch, operating up to 13,300 RPM. optimized for 4.5"angle grinders. 3" 3/8 arbor new product available

- 【MATERIAL】Proprietary aluminum oxide grain for long life and fast cutting.double fiberglass mesh reinforced for further safety and durability

- 【PERFORMANCE】Skinny 0.045" cutting wheel design for fast burr free cutting. Perfectly compatible with all 4 1/2 inch angle grinders with 7/8-inch arbor, operating up to 13,300 RPM and 80M/S

- 【APPLICATION】Tough abrasive cutting discs are perfect for super-fast, clean cutting in carbon steel, stainless steel, pipe, cast iron, copper and other ferrous metals

- 【SAFETY TIPS】Please use all necessary protective gear when you use these cutting blade

- 25 Pack Premium Metal Cutting Discs

- 4-1/2" x 1/16" Cut Off Wheel with 7/8" Arbor

- 1/16 Inch (.0625") Thickness for Long Life and Increased Durability

- Compatible with 4.5" Angle Grinder

- Capable of cutting fiberglass, plastic, iron, steel, stainless steel, and other ferrous metals

- Premium and Value: This 10-pack 4-1/2 x 7/8-inch metal/stainless steel cut-off wheel set is specially formulated for fast cutting in metals and stainless steel

- Safe but Durable Material: Bonded with corundum and white alundum grain and reinforced by double fiberglass mesh, these cutting discs perform much more aggressive cutting in metal and stainless with safety and longer service life

- Precise and Efficient Cutting: 3/64-inch ultra thin design for fast burr-free cutting with minimal material loss, making the cutting project more precise and efficient

- Great Performance: Perfectly compatible with all 4-1/2 inch angle grinders with 7/8-inch arbor, operating up to 13,000 RPM and 80M/S

- Versatile Applications: Tough abrasive cutting discs are perfect for super-fast, clean cutting in carbon steel, stainless steel, pipe, iron, copper and all other ferrous metals

- VERSATILE CUTTING PERFORMANCE: The Benchmark Abrasives 6 inch cut off wheels for metal with a 7/8" arbor is perfect for cutting metal, steel, metal pipes, tubes, flat sheets, shipbuilding, rail, and general metal fabrication. Experience precision in every cut with our expertly designed angle grinder cutting disc. Used by craftsmen and DIY enthusiasts these grinding wheels meet all your needs with ease.

- QUALITY CUTTING WHEEL: The professional Type 1 angle grinder metal cutting disc is completely flat and suitable for grinding operations. The grinder wheels are designed to be your versatile companion. This grinder cutting wheel provides consistent, sharp, burr-free cuts without compromising hardness. The durable cut off wheel tool maintains its integrity even after extensive use, ensuring your projects are completed smoothly.

- PRECISION ENGINEERING, SMOOTH CUTS: Cutting operations with our professional metal cut off wheel is efficient for stainless steel, aluminum, and other metals. With an impressive RPM of 11000, this grinder cutting wheel offers smooth cuts and minimal vibrations during use. Boost your productivity with a high cutting rate cutting disc that ensures cost-effectiveness with every cut.

- MULTIPLE APPLICATIONS & COMPATIBILITY: Compatible with angle grinders, die grinders, high-speed saws, & more, these cutting discs for angle grinder have many uses. Crafted from high-speed steel material, the cut off wheel is designed to last through the toughest projects. The Benchmark Abrasives 6 inch cutting disc fits Dewalt, Milwaukee, Makita, Bosch, Metabo, Ryobi, Black & Decker, Kobalt, Craftsman, Skil, Porter Cable, Ridgid 6” angle grinders and virtually all other brands.

- CUTTING WHEELS YOU CAN TRUST: Our 6 inch grinding wheel is manufactured with premium materials that exceed ANSI and EU European standards. We are dedicated to delivering high-quality cut-off wheels to our customers. Your satisfaction is our priority and the lifeline of our brand. Enjoy the confidence of using angle grinder attachments that professionals trust.

- 25 Pack Premium Metal Cutting Discs

- 3" x 1/16" Cut Off Wheel with 3/8" Arbor

- 1/16 Inch (.0625") Thickness for Long Life and Increased Durability

- Compatible with Die Grinder, Air Cut Off Tool and Electric Cut Off Tool

- Capable of cutting fiberglass, plastic, iron, steel, stainless steel, and other ferrous metals

- Diamond rimmed wheels deliver up to 100X longer cutting life and durability when compared to one standard bonded cut-off disc

- Ideal for dry cutting of metal, rebar, angle iron, cast iron, stainless steel, clloy steel, aluminum, different types of pipes and sheet metal

- Advanced Electro-Plating Process for even distribution of diamond abrasive cutting edge for better control and precision cutting

- Diamond technology is safer to use versus bonded discs by providing more control, less sparks and less dust

- Solid steel wheel body greatly reduces risk of breakage for added safety, diamond rimmed do not shatter or break when dropped

- LONGEST LASTING:Cut off wheels feature metal center and ultra-thin 0.040" thickness. 50 pieces cutting disc for metal & stainless steel meet ANSI safety requirements. Grinder Wheel Dimensions: 4 1/2"x0.040"x7/8"

- PERFECT ALUMINUM:4 1/2 cut off wheel is made with a proprietary combination of alumina particles for aggressive cutting action, providing the industry's best balance of cut life, cut rate, cut accuracy, power requirements and heat build-up, to give you unmatched cut time, consistent precise integrity, moderate power requirements and relatively low heat build-up

- FITS ANY ANGLE GRINDER:50 PCS cut-off wheels for metal & stainless steel fast burr-free cutting feature 4 1/2"x0.040"x7/8" , compatible with Die Grinder, Air Cut Off Tool and Electric Cut Off Tool

- MULTIPLE UESES:Cut off wheels 4 1/2 inch are designed for cutting fiberglass, steel, iron, plastic, stainless steel including rebar, steel pipe, structural & galvanized steel, sheet metal, structural tubing, black steel , and other ferrous metals

- Attention Please:Cutting disc is made in accordance. Before using these, please wear all applicable safety gear when using these discs (eyes/ears/face/hands/body/etc)

- 26 Pack Premium Metal Cutting Discs

- High Performance Thin 6" x .045 Cut Off Wheel

- Ultra-thin design for minimal material loss

- Great Choice for cutting various metals

- Proprietary aluminum oxide grain for agressive cutting action

- 25 Pack Depressed Center Metal Cutting Discs

- High Performance 4.5" Depressed Cut Off Wheel

- Ultra-thin design for minimal material loss

- Great Choice for cutting various metals

- Proprietary aluminum oxide grain for agressive cutting action

Our Review Process

To ensure you get reliable product recommendations, we follow a detailed review methodology that includes:

- Market Research: Scanning best-selling and trending products in this category.

- User Feedback: Reviewing customer reviews, star ratings, and complaints.

- Hands-On Testing: Trying select products ourselves when feasible.

- Feature Comparison: Evaluating specs, durability, pricing, and safety.

- Expert Opinions: Consulting with niche experts or credible reviewers.

We independently select the top 10 options based on value, quality, and usability. To learn more, visit our detailed review process.

Key Considerations Before Buying Cut-off Wheels for Stainless Steel

1. Material Composition

When selecting cut-off wheels for stainless steel, it is crucial to consider the material composition of the wheel. Cut-off wheels are typically made from aluminum oxide, zirconia, or ceramic grains. For stainless steel applications, choosing wheels with zirconia or ceramic grains can offer better performance due to their durability and cutting efficiency.

2. Wheel Thickness

The thickness of the cut-off wheel plays a significant role in its performance. Thicker wheels tend to provide more stability and are less likely to break, while thinner wheels cut faster and produce less waste. A thickness of 1/16 inch is commonly preferred for stainless steel cutting tasks, providing a good balance between durability and cutting speed.

3. Diameter of the Wheel

The diameter of the cut-off wheel must match the specifications of the tool you will be using. Common sizes include 4.5 inches, 5 inches, and 7 inches. Ensure that the wheel’s diameter is compatible with your angle grinder or cut-off tool to guarantee safe and effective operation.

4. RPM Rating

Every cut-off wheel comes with a maximum revolutions per minute (RPM) rating. It is essential to choose a wheel that is rated for use at the RPM of your grinder to prevent accidents or wheel failure. Always refer to the manufacturer’s specifications to ensure compatibility.

5. Type of Bonding Agent

Cut-off wheels may use different bonding agents, such as resin or epoxy. The type of bonding agent affects the wheel’s durability and performance. Resin-bonded wheels are commonly used for stainless steel due to their ability to withstand high temperatures and provide a clean cut.

6. Application Requirements

Consider the specific application requirements, such as the type of stainless steel being cut, the thickness of the material, and the desired finish. For instance, some applications may require finer cuts, while others may prioritize speed. Matching the cut-off wheel to your specific needs will enhance efficiency and results.

7. Brand Reputation and Reviews

Researching reputable brands and reading customer reviews can provide insights into the performance and reliability of different cut-off wheels. Established brands often have a proven track record of quality and customer satisfaction, which can help guide your purchasing decision.

8. Price vs. Quality

While it might be tempting to opt for cheaper options, investing in high-quality cut-off wheels can pay off in the long run. Quality wheels tend to offer better performance, longer life, and more efficient cutting. Evaluating the balance between price and quality is key to ensuring you make a worthwhile investment.

9. Safety Features

Safety is paramount when using cut-off wheels. Look for wheels that adhere to safety standards and have features such as reinforced construction for added durability. Additionally, ensure you have the appropriate personal protective equipment (PPE) when operating cutting tools.

10. Compatibility with Tools

Finally, ensure that the cut-off wheels you choose are compatible with the tools you plan to use. This includes checking the arbor size and mounting options, as different tools may require specific wheel types or attachments.

FAQs

What are cut-off wheels for stainless steel?

Cut-off wheels for stainless steel are abrasive discs designed specifically for cutting through stainless steel materials. They are made from a variety of materials, including aluminum oxide and zirconia, and are engineered to provide efficient cutting while minimizing heat buildup, which can lead to material distortion or damage.

How do I choose the right cut-off wheel for stainless steel?

When selecting a cut-off wheel for stainless steel, consider factors such as the thickness of the material you’re cutting, the type of stainless steel, and the specific application. Look for wheels labeled for stainless steel use, as they typically have specific bonding agents and abrasive formulations designed to optimize performance and reduce contamination.

What size cut-off wheel should I use?

The size of the cut-off wheel you should use depends on the tool you are operating and the depth of cut needed. Common sizes range from 4 inches to 14 inches in diameter. Always check your tool’s specifications for compatible wheel sizes.

Can I use cut-off wheels for other materials?

While cut-off wheels for stainless steel are optimized for that material, some can also be used on other metals such as aluminum and mild steel. However, it’s important to use the appropriate wheel for each material to ensure the best performance and to avoid contamination or damage.

What safety precautions should I take when using cut-off wheels?

When using cut-off wheels, always wear appropriate personal protective equipment (PPE), including safety goggles, gloves, and hearing protection. Ensure that the wheel is properly mounted and that the tool is in good condition. Follow the manufacturer’s instructions for use and maintain a safe distance from others while cutting.

How long do cut-off wheels for stainless steel last?

The lifespan of cut-off wheels depends on various factors, including the wheel’s quality, the material being cut, and the cutting technique employed. Generally, using a steady hand and proper technique can extend the life of the wheel. Always monitor the wheel for wear and replace it when it becomes dull or damaged.

Are there specific brands recommended for cut-off wheels for stainless steel?

Several well-known brands produce high-quality cut-off wheels for stainless steel, including Norton, 3M, DEWALT, and Makita. It is advisable to read reviews and check product specifications to find the best option for your specific needs.

Can cut-off wheels create heat when cutting stainless steel?

Yes, cut-off wheels can generate heat during the cutting process, which can lead to material distortion or damage if not properly managed. To minimize heat buildup, use the correct wheel for the job, maintain a steady cutting speed, and consider using coolant where applicable.

What is the difference between cut-off wheels and grinding wheels?

Cut-off wheels are designed primarily for making straight cuts through materials, while grinding wheels are intended for grinding, shaping, and finishing surfaces. Cut-off wheels are typically thinner than grinding wheels and are optimized for cutting rather than material removal.

The Bottom Line

In conclusion, the selection of the best cut-off wheels for stainless steel is crucial for achieving clean and efficient cutting results. Our list of the top 10 products was meticulously curated based on various factors, including performance, durability, user reviews, and compatibility with different cutting tools. We evaluated each product’s specifications, materials, and user experiences to ensure that they meet the rigorous demands of working with stainless steel. By taking into account both expert opinions and customer feedback, we aimed to provide a comprehensive resource for both professionals and DIY enthusiasts.

By following our recommended list, you can enhance your cutting experience and productivity while minimizing the risk of material damage and tool wear. Each of the products highlighted has proven to deliver excellent performance, making them suitable for a range of applications, whether you’re working in a workshop, on-site, or at home. Investing in the right cut-off wheels will not only save you time but also improve the quality of your work, allowing you to tackle stainless steel projects with confidence and precision.